Automatic Push-down Panel Bender

◆2000 [mm] Max bending length

◆1250 [mm] Max bending width

◆200 [mm] Max bending height

◆0.2 [s/bend] Bending speed

◆

1 [year] Warranty period

主要参数 Main Parameters | 型号 Model | ||

| BDC1500 | BDC2000 | BDC2500 |

Max Bending Size (L*W*H, mm) | 1500*1250*200 | 2000*1250*200 | 2500*1250*200 |

Max Bending Thickness (mm) | 1.5-2.5 | 1.5-2.5 | 1.5-2.5 |

Min Bending Thickness (mm) | 0.35 | 0.35 | 0.35 |

Bending Speed (s/bend) | 0.2 | 0.2 | 0.2 |

Number of Controlled Axis | 13 | 13 | 13 |

Overall Dimensions (L*W*H, mm) | 4400*2000*2750 | 5000*2700*2950 | 5700*3200*3050 |

Power |

Three-phase 380V, 50Hz/60Hz (custom-made) | ||

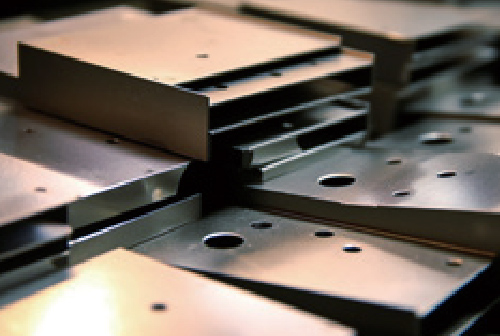

The push-down arm uses upper and lower grippers to clamp workpieces even when there are pores, dents or they are in complex shapes. In a word, such feeding mode has low demanding on the quality of sheet surface.

* Max bending speed: 0.2s/bend

* Bend multiple sides after one positioning

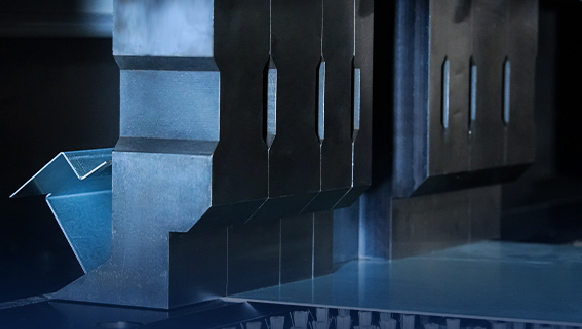

Its universal bending tools are made of high-strength alloy/die steel and have got through dozens of procedures including solid forging, tempering and quenching in order to bend for millions of times.

* No additional adjustment nor tool change

* More resistant to wear for longer service life

In the context of graphically visual programming, workers only need to type in bending data as needed, with no manual programming. Automation ranges from loading, positioning, bending to unloading. No needless shutdown but higher speed.

During work, workpiece is usually pushed in and out by push-down arm automatically. Handheld feeding, positioning and bending become needless. With less manual intervention, potential safety hazards arising from misoperation are also minimized by its automatic work.

In this age of industrialization, panel bender is gradually replacing traditional bending machines because it is a strong performer in bending speed, labor force, safety, ease of use, workpiece consistency and automation. It will surely develop into a new favorite of global sheet metal processing enterprises.