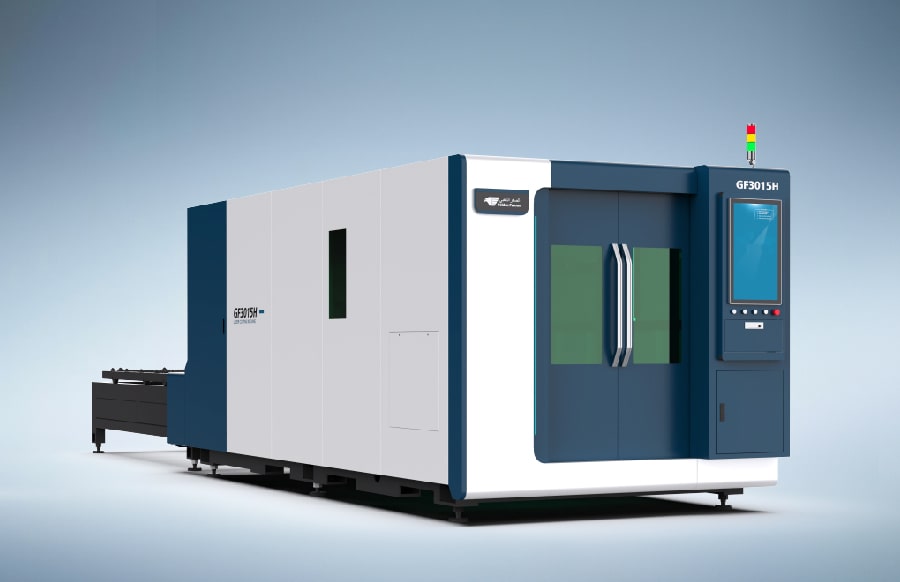

GF3015H Pro Series Ultra-high-power Sheet Laser Cutting Machine

◆ 12-30 [kW] Laser power

◆ 3080*1530 [mm] Max sheet size

◆ 180 [m/min] Max no-load speed

◆ 3000 [kg] Max load of double exchange platforms

◆ 2 [years] Warranty period

Main Parameters | Model |

| 3015H (4th Generation) |

Laser Power (kW) | 12-30 |

Working Area (L*W, mm) | 3080*1530 |

X/Y-axis Positioning Accuracy (mm) | ±0.05 |

X/Y-axis Repositioning Accuracy (mm) | ±0.02 |

Max No-load Speed (m/min) | 180 |

Max Load of Platforms (kg) | 3000 |

Overall Dimensions (mm) | 8440*2270*2340 |

Power Supply | Three-phase 380V, 50Hz/60Hz |

In the self-developed intelligent CNC system, there are a sea of advanced cutting crafts available, such as, perfect finish cut, pierce-through deslagging, co-edge cutting and traceless micro-joint, so that super-thick sheet is cut at fast speed and high quality.

* Cut 60mm thick sheet in batch

* Cut 90mm thick sheet at most

After years of technical development, we have mastered a mass of core technologies and achieved the self-research and self-production of 80%+ core components. With that, it is much easier for users to apply for later maintenance and repair.

* Intelligent bus-based CNC system

* Auto nesting software

* All-fiber laser generator

* Auto collision-proof laser cutting head

* Heavy-duty machine tool and accessories

* Quality transmission system

The machine, with double cameras, can secure both workers and itself. Negative-pressure dust removal system can control air vents based on cutting position to discharge smoke and dust rapidly and allow for smoke-free effects.

* Fully-enclosed structure

* Zoning ventilation system

* Smart negative-pressure dust removal

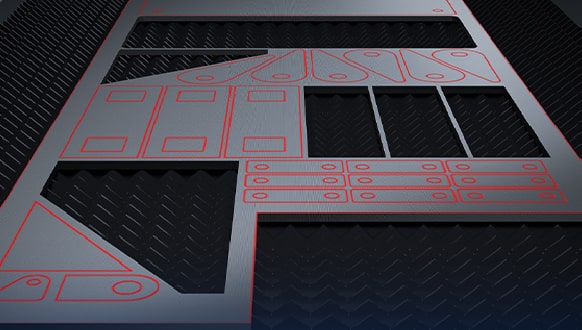

With optimal algorithms, the auto nesting software can nest sheets as much as possible. Users are entitled to change cutting order and optimize cutting path at will to maximize sheet utilization.

* Auto programming

* Efficient nesting

* A wealth of typesetting modes

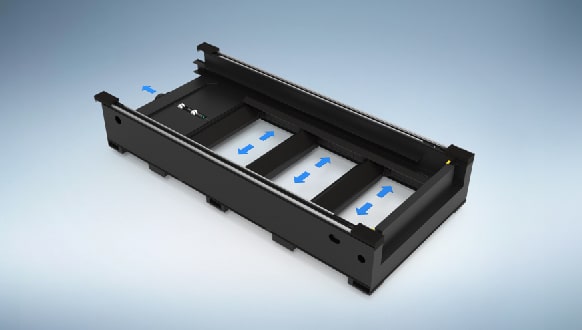

This machine tool is hollow and unconnected internally, so as to cut off heat transfer and effect on cutting precision. With the help of burn-proof graphite, it outperforms in stability, shock resistance and service life.

* Steel plate and tube welding together

* Stress relief annealing

* Secondary aging treatment

* Fine finishing by super-large planomiller